Unmatched Excellence in Metal Fabrication: Your Guide to Precision CNC Turning Parts Factories

In today’s highly competitive industrial landscape, the importance of high-precision manufacturing cannot be overstated. Industries ranging from aerospace and automotive to medical devices and electronics demand components that are not only durable and reliable but also manufactured with extreme accuracy and efficiency. This is where metal fabricators, especially precision CNC turning parts factories, come into play, offering tailored solutions that meet the most stringent standards of quality and consistency.

Understanding the Role of Metal Fabricators in Modern Industry

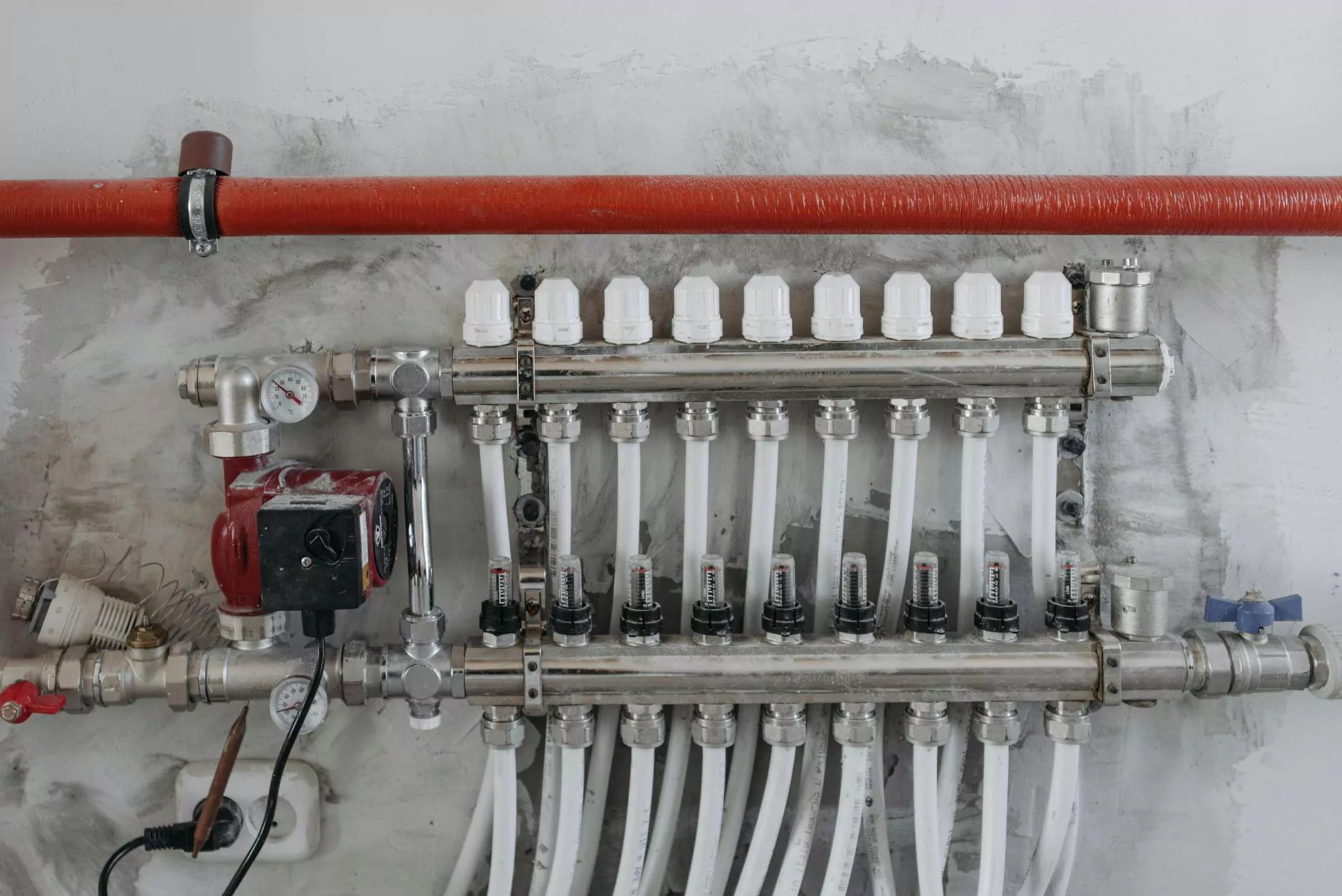

Metal fabricators serve as the backbone of manufacturing sectors, transforming raw metal materials into complex, precision-engineered components. These fabricators leverage advanced machinery, such as Computer Numerical Control (CNC) machines, to produce parts that meet exact specifications with minimal tolerance deviations. Their role is critical in ensuring that end-products perform reliably in demanding operational environments.

The Rise of Precision CNC Turning Parts Factories: A Game Changer

The evolution of CNC technology has revolutionized metal manufacturing, leading to the emergence of precision CNC turning parts factories that specialize in producing highly intricate and precise components at scale. These factories utilize state-of-the-art CNC lathes, which allow for the fabrication of complex geometries with unparalleled accuracy and repeatability.

Why Choose a Precision CNC Turning Parts Factory?

- Superior Precision: Produces components within tight tolerances, often as low as ±0.01mm.

- Enhanced Consistency: Ensures uniformity across large production runs, maintaining exact dimensions and finishes.

- Complex Geometries: Capable of manufacturing intricate features that are impossible with traditional machining methods.

- Cost Efficiency: Reduces material waste and labor costs through automated, high-speed production.

- Quick Turnaround: Delivers rapid prototyping and mass production, meeting tight deadlines.

Deepmould.net: A Leading Name in Metal Fabrication and Precision Manufacturing

Among the industry leaders, deepmould.net has established itself as a premier metal fabricator specializing in precision CNC turning parts. Their commitment to quality, innovation, and customer satisfaction has propelled them to the forefront of the metalworking industry.

Why Deepmould.net Stands Out

- Advanced Equipment: Utilizes the latest CNC turning technology, capable of handling diverse and complex materials like stainless steel, aluminum, brass, and titanium.

- Rigorous Quality Control: Implements comprehensive QC protocols, including in-house metrology and inspection, ensuring parts meet or exceed industry standards.

- Custom Solutions: Offers tailored manufacturing services to meet specific client needs, from prototyping to large-volume production.

- Industry Certifications: Holds ISO 9001:2015 certification, demonstrating a commitment to quality and continuous improvement.

- Responsive Customer Service: Provides expert technical support and consultation, fostering long-term partnerships.

Key Technologies Used in Precision CNC Turning Parts Factories

Modern precision CNC turning factories like deepmould.net employ a diverse array of cutting-edge technologies to maximize accuracy and efficiency. Some of these include:

1. Multi-Axis CNC Lathes

Enable complex movements and multi-dimensional machining, allowing for the production of intricate parts with tight tolerances.

2. Automated Tool Management

Ensures rapid tool changes, reducing downtime, and increasing productivity while maintaining high precision standards.

3. CAD/CAM Integration

Facilitates seamless translation of design specifications from digital models to manufacturing processes, enhancing accuracy and reducing errors.

4. In-Line Inspection Systems

Allow real-time quality monitoring, ensuring each part adheres strictly to design specifications, reducing rework and waste.

Material Selection and Its Impact on Manufacturing Precision

The choice of material plays a pivotal role in the manufacturing process, influencing both the machining strategy and the final product quality. High-grade metals like stainless steel, titanium, and aluminum alloys are commonly used in precision CNC turning for their excellent machinability, durability, and corrosion resistance.

Proper material selection ensures that parts retain their structural integrity under operational stresses, especially in demanding applications such as aerospace or medical devices. Deepmould.net offers expert guidance on selecting the right material based on application requirements, ensuring optimal performance and longevity of finished components.

Ensuring Quality and Precision in CNC Turning Manufacturing

Achieving top-tier quality in precision CNC turning parts involves a multifaceted approach:

- Design Optimization: Collaborate with engineers to refine CAD models for manufacturability and cost-efficiency.

- Tooling Precision: Use high-quality cutting tools and fixtures to maintain stability and accuracy.

- Process Control: Implement strict monitoring of machining parameters like speed, feed rate, and tool wear.

- Inspection & Testing: Conduct comprehensive dimensional and surface finish inspections using coordinate measuring machines (CMMs) and other precision instruments.

- Continuous Improvement: Regularly review processes and incorporate technological advancements to enhance precision and productivity.

The Future of Metal Fabrication and Precision CNC Turning

The landscape of metal fabrication is rapidly evolving with innovations such as automation, artificial intelligence, and additive manufacturing complementing traditional CNC methods. These advancements are set to further elevate precision and efficiency, enabling factories to produce even more complex, lightweight, and durable parts.

In particular, digital twin technology—which creates virtual replicas of manufacturing processes—will allow real-time optimization and predictive maintenance, drastically reducing downtime and defects.

At the forefront of this technological revolution, deepmould.net and similar metal fabricators are investing heavily in R&D, ensuring they continue to deliver top-quality, high-precision components tailored to the evolving needs of global industries.

Partnering with a Reliable Precision CNC Turning Parts Factory

Choosing the right manufacturing partner is crucial for success in any high-stakes industry. When selecting a precision CNC turning parts factory, consider factors such as:

- Experience and Expertise: Proven track record in producing complex, high-precision parts.

- Technological Capabilities: Access to advanced CNC equipment and inspection tools.

- Quality Management: Certifications and quality assurance protocols.

- Flexibility: Ability to handle custom designs and varying production volumes.

- Customer Support: Responsive communication and technical assistance.

Deepmould.net exemplifies all these qualities, making them an ideal partner for industries seeking precision, reliability, and excellence in manufacturing.

The Bottom Line: Why Precision and Quality Matter

In conclusion, metal fabricators, especially precision CNC turning parts factories, are instrumental in delivering components that meet the highest standards of quality, precision, and performance. As industries continue to push for technological advancements and better efficiencies, the role of specialized factories like deepmould.net becomes increasingly vital.

By prioritizing excellence in manufacturing, leveraging cutting-edge technology, and fostering long-term partnerships, your business can gain a competitive edge and achieve remarkable success in today’s demanding marketplace.

Investing in precision CNC turning solutions ensures that your products not only meet current standards but also set new benchmarks for quality and innovation within your industry.

Contact Deepmould.net Today for Your Precision Manufacturing Needs

For companies seeking a trusted, experienced, and innovative partner in metal fabrication, deepmould.net offers comprehensive solutions tailored to your unique requirements. Reach out today to discover how their expertise in precision CNC turning parts can elevate your manufacturing processes and propel your products to market success.